FLUID REQUIREMENTS

Electrically controllable smart fluid derives from their ability to provide simple, quiet, rapid response and interfaces between electronic controls and mechanical systems.

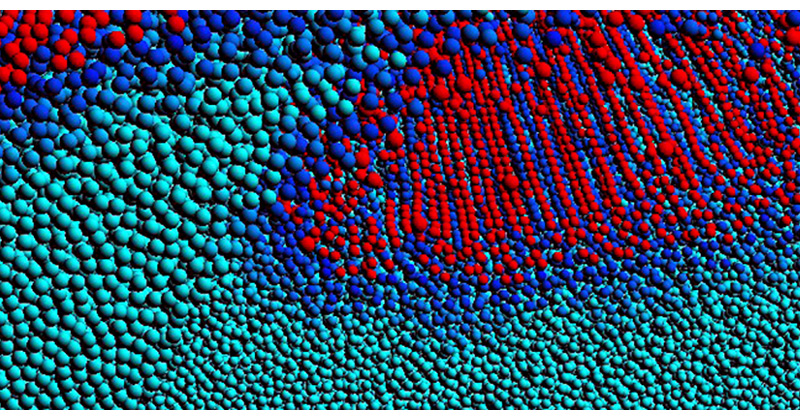

Under the influence of electric field particles, the solid phase tends to form chains and columns along the direction of an applied electrical field. This results in enhanced shear stress and such fluid exhibits increased resistance to flow. Apparent viscosity increases as well as elastic modulus, the increased stiffness is observed, the transition has been described as liquid-solid.

Electrically controllable smart fluid derives from their ability to provide simple, quiet, rapid response and interfaces between electronic controls and mechanical systems.

Under the influence of electric field particles, the solid phase tends to form chains and columns along the direction of an applied electrical field. This results in enhanced shear stress and such fluid exhibits increased resistance to flow. Apparent viscosity increases as well as elastic modulus, the increased stiffness is observed, the transition has been described as liquid-solid.

Smart fluid characteristics

Smart fluid characteristicsElectrorheological a smart fluid is a fluid whose properties "viscosity" can be changed by applying an electric field.

Viscosity

The dynamic viscosity of rheological fluid depends on dynamic viscosity of the base liquid, the volume fraction of solid particles, the amount and type of additives used to control particle settling and the shear rate at which viscosity is measured. The water-based fluids have a higher particle volume fraction than the other oil-based fluids.

The additives in fluid cause the viscosity to increase rapidly when shear rate decreases. Apparent viscosity of the rheological fluid becomes lower when shear rate increases until it eventually reaches a steady state value. This phenomenon is called "a shear thinning" character.

For oil-based fluids, the apparent viscosity reaches a steady state value at a relatively low shear rate in a few hundred of seconds.

For the water-based fluids, the apparent viscosity starts higher at a low shear rate and continues to drop over a much longer range of shear rate. In this case, an asymptotic, steady state value will not be reached until the shear rate increases up to several thousand or even ten thousand second. At these high rates, the water-based fluid will actually have lower apparent viscosity than oil-based fluid.

Power requirements

Electrorheological fluid devices in average application have power requirements of about 50W. The difference is in applied voltage and curren, the electrorheological fluid devices require high voltage 2–5kV and low current 1–10mA power supply.

Smart fluids have a great potential to modernize the automotive industry.

The electrorheological fluid must be a user friendly engineering material, the fluid should have a high boiling point and low freezing point, it should not be abrasive or attack common engineering materials; it should have a long storage and working life; it should show a minimal tendency to settle out, it can be used with ordinary rubber seals, it must be non toxic and safe to use.

The electrorheological fluid must be a user friendly engineering material, the fluid should have a high boiling point and low freezing point, it should not be abrasive or attack common engineering materials; it should have a long storage and working life; it should show a minimal tendency to settle out, it can be used with ordinary rubber seals, it must be non toxic and safe to use.